languageSelector_au

languageSelector_au Argentina | español

Argentina | español Bosna i Hercegovina

Bosna i Hercegovina Česká republika | czech

Česká republika | czech Chelsea Building Products

Chelsea Building Products China | 中文

China | 中文 Deutschland | deutsch

Deutschland | deutsch España | español

España | español Eλλάδα | Eλληνική

Eλλάδα | Eλληνική France | français

France | français India | english

India | english Indonesia | english

Indonesia | english International | english

International | english  Italia | italiano

Italia | italiano Kosovës

Kosovës Lietuva | Lietuvos

Lietuva | Lietuvos Magyarország | magyar

Magyarország | magyar México | español

México | español Nederland | nederlands

Nederland | nederlands Österreich | deutsch

Österreich | deutsch Polska | polski

Polska | polski România | românesc

România | românesc Slovenija | slovenščina

Slovenija | slovenščina Slovensko | slovenský

Slovensko | slovenský Srbija | srpski

Srbija | srpski UK | english

UK | english Ukrayina | українська

Ukrayina | українська USA | english

USA | english الامارات العربية المتحدة | العربية

الامارات العربية المتحدة | العربية aluplast and Think Manufacturing Lead PVC Recycling

Melbourne, Australia

In an industry-leading initiative, aluplast and Think Manufacturing are revolutionising polyvinyl chloride (PVC) recycling in Australia. These leaders are setting new sustainability benchmarks by repurposing uPVC offcuts from window and door manufacturing.

PVC is a versatile and durable polymer used in various products, from flooring and cables to medical supplies. Despite being one of Australia's most used polymers, PVC has historically had a poor environmental reputation due to limited recycling efforts.

uPVC is the leading material for insulated windows and doors in Europe and North America. With the introduction of the 7-star energy rating for new homes, uPVC insulated windows and doors are now poised for significant growth in Australia, offering superior thermal performance at an affordable cost.

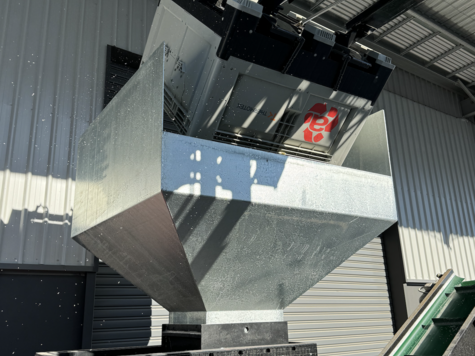

aluplast, a global leader in thermally efficient uPVC window and door profiles, tackles the PVC recycling challenge head-on. The company collects uPVC offcuts from its fabricator network across Australia, shredding and granulating them at its state-of-the-art facility in Dandenong South, Melbourne, for reuse.

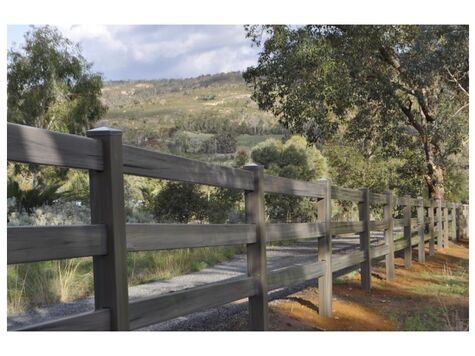

Its collaboration with Think Manufacturing epitomises a successful circular economy model. Led by founder Jack Fitzgerald, Think Manufacturing uses aluplast recycled uPVC to produce fencing and decking components.

Fitzgerald underscores the importance of this initiative: "PVC has traditionally been problematic due to increasing production and lack of recycling solutions. Our partnership with aluplast directly addresses this issue."

In pursuit of further innovation, Think Manufacturing is partnering with CSIRO to develop an AI-powered PVC analyser. This pioneering technology will streamline the recycling process by accurately identifying the composition of individual PVC formulations. Fitzgerald believes this analyser could revolutionise the industry, enabling the production of high-quality recycled products. He states, "The potential is huge. We can take rigid PVC from any source and produce a repurposed finished product."

The collaboration between aluplast and Think Manufacturing showcases the power of industry leaders working together to achieve a common goal. "Closing the loop on the 'plastic pipeline' has been our life's work," Fitzgerald says. "We aim to build a house predominantly from recycled PVC materials, making it an affordable, realistic product within the next five years."

Ben Webster, Managing Director of aluplast Australia, notes that the company has incorporated recycled materials into its uPVC window and door profiles for over a decade. Some profiles used in Australia now contain more than 80% recycled content.

"Ensuring we divert manufacturing offcuts from landfill is vitally important," he says. "Our recycling program keeps all uPVC within the material cycle, not in landfill."

Webster emphasises that uPVC's excellent recyclability and low embodied carbon make it the most sustainable material for windows. He also highlights the investment by aluplast fabricators in the sustainability cycle, purchasing stackable uPVC recycling crates that fold flat to a third of their volume for efficient interstate transport. To further reduce offcut volumes for transport, aluplast plans to provide mini shredders to interstate customers later this year.

As more Australian builders embrace the most direct route to meet the new 7-star energy rating requirements, aluplast is increasing production and consequently recycling volumes. "Quality uPVC windows and doors offer significant energy savings. More architects and builders are discovering that aluplast’s uPVC systems are up to 40% more energy efficient than standard double-glazed aluminium systems," Webster says."aluplast products provide the most sustainable and affordable solution for making Australian homes thermally efficient.”

Webster emphasises that aluplast’s innovation and investment in sustainability demonstrates their care for the markets they operate in: “Our products offer a way for Australians to reach the mandated 7 star rating and beyond in a sustainable and economic way.”

aluplast profile recycled into Australian building products